Over the last couple of years 3D printing has taken off on a high note even though the technology has been around for more than a decade now. The interest in 3D printing has increased considerably as companies have started to make this technology more affordable and consumer friendly. 3D printing is basically a manufacturing technology where products are created through addition of layers with the help of the 3D printers. With the help of this technology it is possible to create almost anything without much of an effort. The products are created through the automated process known as Computer Aided Manufacturing or CAM. The basic idea is to create the design of the material on the computer and the design is fed into the printer where the product is created layer by layer.

Over the last couple of years 3D printing has taken off on a high note even though the technology has been around for more than a decade now. The interest in 3D printing has increased considerably as companies have started to make this technology more affordable and consumer friendly. 3D printing is basically a manufacturing technology where products are created through addition of layers with the help of the 3D printers. With the help of this technology it is possible to create almost anything without much of an effort. The products are created through the automated process known as Computer Aided Manufacturing or CAM. The basic idea is to create the design of the material on the computer and the design is fed into the printer where the product is created layer by layer.

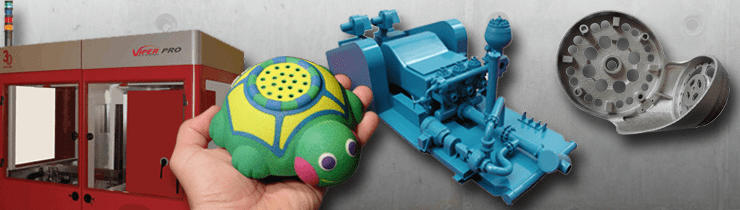

The advancement in technology has made it possible to come up with new ideas and innovation through which 3D printing can reach a new level. Presently the 3D printing technology is not only used for the creation of prototypes but even finished products. Recently there was news that some students from Belgium took up a challenge to produce an electric car through 3D printing. The most interesting part of this challenge was that they were able to 3D print an electric car. The car was named Areion and was printed with the help of a huge stereolithography printer which is capable of producing objects up to seven feet long. The car is powered by an 85KW motor and a 50 volt lithium ion battery. It can attain a speed of 0-62 in a mere 3.2 seconds and is capable of reaching maximum speed of 88mph. The challenge that is held every year in the UK by Formula student makes sure that the cars are tested before the trial. The Areion underwent a number of tests like rain test, fuel efficiency test, acceleration and safety test.

The best thing about using 3D printing technology is that once the design is complete, the production can be completed quite quickly. The car was developed within three weeks and it has already completed races in different countries like UK, Germany. Apart from manufacturing automobiles, 3D printing is going to benefit a lot of other fields like customized consumer products, medical applications, replacement parts production and architecture.

Recently an eighty three old year old woman was transplanted with an artificial jaw that was manufactured with the help of 3D printing. The possibilities that are in offering seem to be huge and chances are that nothing will remain impossible in the near future. Home based 3D printing might gradually lead to more and more products being produced at home where retail outlets and malls might suffer badly. The form of manufacturing offered by this technology will not only prove to be cheaper but help in fast manufacturing of products. Already the 3D printing industry has an estimated value of around 1.7 billion dollars and is expected to rise sharply over the next five years or so.

Thanks for any other fantastic post. Where else may just anyone get that type of information in such a perfect way of writing? I’ve a presentation next week, and I am at the look for such information.

Awaiting more posts!