Systems for 3D scanning find use in various industries like aerospace, automotive, manufacturers and medical. Digital information is captured about an object shape by using equipment using light or laser to measure distance between object and scanner. Small size objects can be easily captured along with full-size skyscraper buildings or aeroplanes.

Real time data is digitized by these equipments which are then incorporated into CAD systems. Unlike handheld devices, conventional scanning equipments require different setups and one need to aim target surfaces directly. 3D scanners that are handheld can easily capture data of large surfaces like boat hulls for creating digital models.

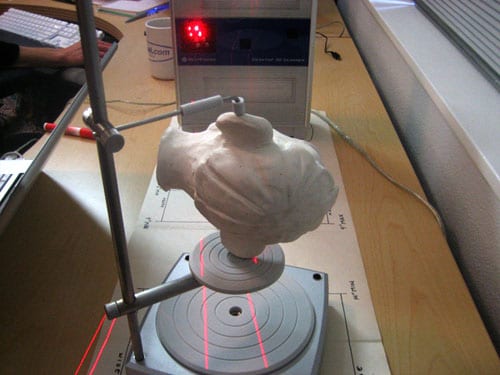

Per second multiple points can be captured by laser 3D scanners with the help of their advanced technology and functionalities. Inspection of production parts happens quite fast with such type of scanners. The 3D scanning methodology helps to provide better quality, good fitting parts as well as reduction in cost. The accuracy percentage differs from equipment to equipment. Different manufacturers use different technology and mechanism to build their products.

Physical measurements are quickly captured for all physical objects. Another significant benefit is that time consumed in the design work can be lessened to a great extent. Manual procedures require huge time and the outcome of the task is often not satisfactory. However, such occurrences rarely happen with 3D scanning as the design of the material is highly enhanced. Costs for sheet metal formation and metal fabrication are reduced to a large extent.